The Greatest Guide To American Plastics

Little Known Facts About American Plastics.

Table of ContentsAmerican Plastics for BeginnersThe Single Strategy To Use For American PlasticsAmerican Plastics for DummiesAmerican Plastics Can Be Fun For EveryoneThe Single Strategy To Use For American Plastics

A little homework can assist you over time. It is difficult to judge its high quality at initial glimpse with the appearance of HDPE pipeline fitting, lots of defects are subjected when making use of, so we can only have an appropriate judgment after usage. As a result, it is necessary to select HDPE pipeline installations made by a professional manufacturer with a good track record and reputation.A technological specialist is essential for a good product, specifically in the production industry, due to the fact that a tiny blunder will certainly bring about the failing of the whole task. HDPE pipelines can replace concrete pipelines in area systems to conserve time and price of fixing damaged or ruptured pipes. HDPE pipeline is additionally a more economical alternative compared to various other piping products in terms of operating and setup costs.

How American Plastics can Save You Time, Stress, and Money.

HDPE pipes are manufactured with solid straight or rounded areas. The pipelines are not fragile and can be conveniently inserted right into a curved location without added jointing or welding.

Chemicals immune to HDPE pipelines can infect the pipe. The pipe does not work with chemicals and does not shed warm or electricity.

HDPE pipes are normally solid and resistant to damages triggered by outside loads, high stress or vibration - https://www.quora.com/profile/Dane-Coffman-3. The pipes can stand up to handling and bend even in cool weather condition. Safe eye liner HDPE internal tubing Smooth Line Pipe Sliding lining using roller combinations Pipeline explosion Plastic pipes systems Building of new pipelines Rust resistance, no leaking, high longevity

Warmth combination, while its challenges exist, can develop strong and reputable joints. Responses: The stamina and toughness of HDPE can be gauged by its capability to withstand temperature levels of around 248F in the short-term or also a constant 230F. If your application includes gas and liquid to accessibility and increase those temperature levels, HPDE piping is a reputable solution.

Some Ideas on American Plastics You Should Know

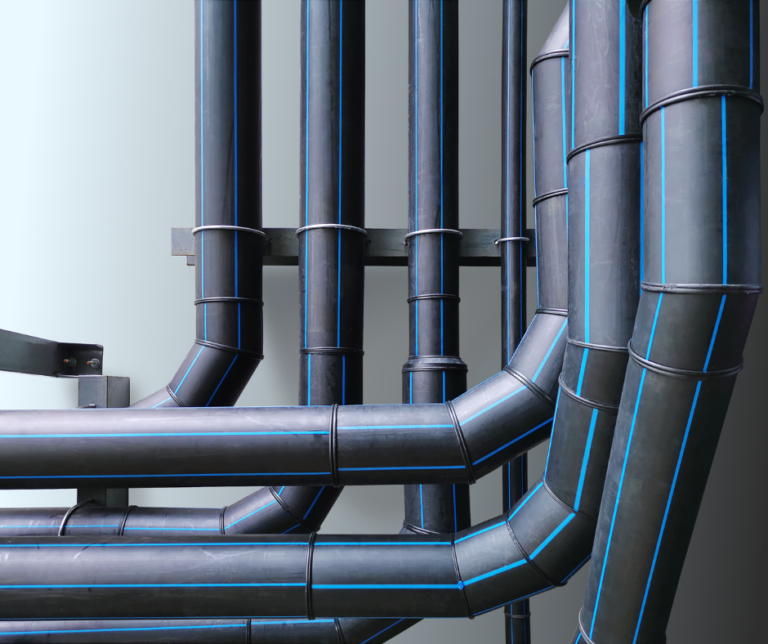

As an example, a drinkable water line/potable pipes is constantly dark with blue stripes and pipes travelling through fluids, fluids under stress, and procedure gases are constantly filled with a yellow or black coat with yellow lines. HDPE pipe material have actually been made use of in the basic industry for over half a century and their outcomes are astonishing, developing self-confidence amongst makers that they are a lot more concentrated on HDPE pipe remedies.

Times because 1991 Removal of material requirements with scale and adjustment. In the stress and anxiety crack resistance test the cellular division needs were deteriorated. It is reasonable to conclude that HDPE pipe constructed today may have.

Each dimension classification is developed keeping in mind the requirements of pressure, circulation rate, and ecological variables of the desired application. By matching the proper HDPE pipeline size to its usage, designers and professionals can maximize performance and extend the life expectancy of their piping systems. Dimension and diameter are related concepts in the context of HDPE pipelines.

Rumored Buzz on American Plastics

As specified previously, pipes with reduced SDR worths are able to stand up to greater pressures, which is an essential consideration in the option process for projects that involve high pressure or important applications. high quality hdpe pipe. Choosing a pipe with an improper SDR could cause system failure, safety threats, and pricey repair work. Picking the correct HDPE pipeline size is vital for the success and efficiency of any type of piping system

Application Specifics: Customize your pipeline size selection to the specific demands of its application, whether for local, industrial, or other uses. Recognizing exactly how the HDPE pipeline will be utilized, the anticipated circulation prices and the pressure requirements are important. High-pressure applications might call for a pipe with a higher wall surface density to stand up to the interior stress and anxieties, while a lower-pressure, high-flow system could focus on diameter size to decrease rubbing loss.

The Buzz on American Plastics

Adhere to these steps: Examine the Application: Identify the pipeline's intended use, consisting of ecological aspects and solution problems. Compute Circulation Rates: Usage industry-standard calculations or software program to approximate the top and standard flow prices. Understand Pressure Demands: Recognize the stress score required based on system demands. Describe SDR: Inspect the typical dimension ratio to locate a pipeline that can handle the needed pressure.

Picking the appropriate HDPE pipe dimension is a fragile balance between many technical specifications and sensible demands - https://www.quora.com/profile/Dane-Coffman-3. Nonetheless, with mindful factor to consider and precise computations, you can make sure the size of the pipeline you select will certainly serve your demands effectively and successfully. Picking the proper HDPE pipeline size is essential for system performance, durability, and cost-effectiveness

Understanding these facets will make certain optimal performance and compatibility throughout your piping system - hdpe pipe fittings go to the website Midland TX. The expected flow rate or quantity of the liquid being moved is one of the primary components in pipe dimension choice. A pipe that is too little can restrict circulation, creating pressure loss and possible obstructions, while an extremely large pipeline might bring about unnecessary expense and minimized system efficiency